Advancing technology through evidence-based research.

Advancing technology through evidence-based research.

Our Technology

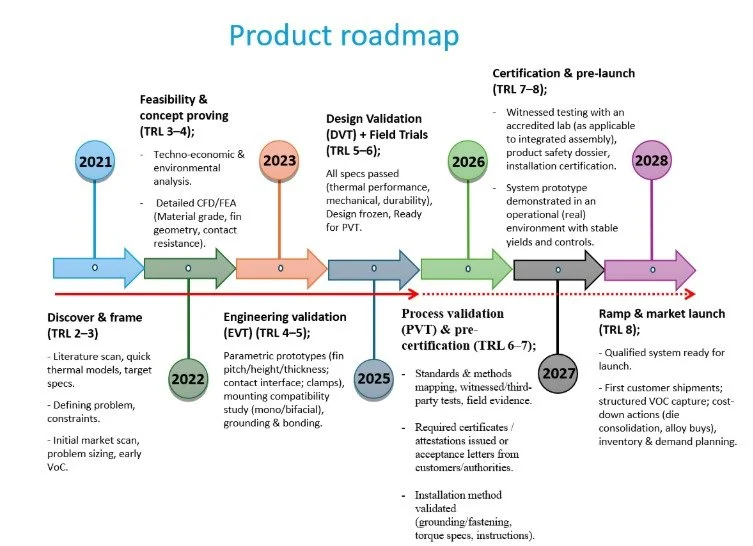

Hybrid Energy Solutions develops and evaluates engineering solutions that improve the performance, durability, and affordability of solar photovoltaic systems, particularly in high-temperature environments.

Our technology development is research-led and evidence-based, progressing from analytical modelling and laboratory work through to field validation and early commercial readiness.

Passive Cooling Heatsink Technology

Solar photovoltaic (PV) modules experience a reduction in electrical efficiency and accelerated material degradation as operating temperatures increase. In hot and high-irradiance environments, such as sub-Saharan Africa and the Middle East, excessive heat buildup at the rear of solar panels is a major limiting factor in long-term system performance.

Hybrid Energy Solutions has developed a passive cooling heatsink technology that integrates directly onto the rear surface of standard solar PV modules. The system is designed to dissipate excess heat naturally, without the need for fans, liquids, electrical input, or moving parts.

Why Passive Cooling?

Solar photovoltaic systems operating in hot climates are subject to sustained thermal stress, which reduces electrical efficiency and accelerates long-term material degradation. While a range of cooling approaches exists, many introduce additional complexity, cost, maintenance requirements, and reliability risks that limit their suitability for large-scale or remote deployment. Passive cooling offers a fundamentally different solution. By requiring no electrical power, the system operates continuously without parasitic energy losses, ensuring that performance gains are not offset by additional consumption. With no moving parts, fluids, or control systems, passive cooling significantly reduces failure risk and maintenance demand, making it particularly well-suited to hot, dusty, and infrastructure-limited environments. The reliance on natural heat conduction and convection provides robust operation under harsh conditions where active cooling systems are vulnerable to mechanical wear, leakage, or power interruption. By reducing module operating temperatures, passive cooling also mitigates thermal cycling and material stress, helping to stabilise voltage output and improve energy yield over the full system lifetime rather than only at peak conditions. In addition, passive cooling solutions can be manufactured using standard aluminium fabrication processes, enabling cost-effective scaling, retrofit compatibility, and straightforward integration with existing PV technologies. The use of aluminium, particularly recycled material, further aligns the approach with circular-economy principles, avoiding consumables, operational emissions, and unnecessary system complexity. For these reasons, passive cooling was selected as the focus of the StegoSolar research programme and developed through simulation, prototyping, and real-world field validation.

How the technology works

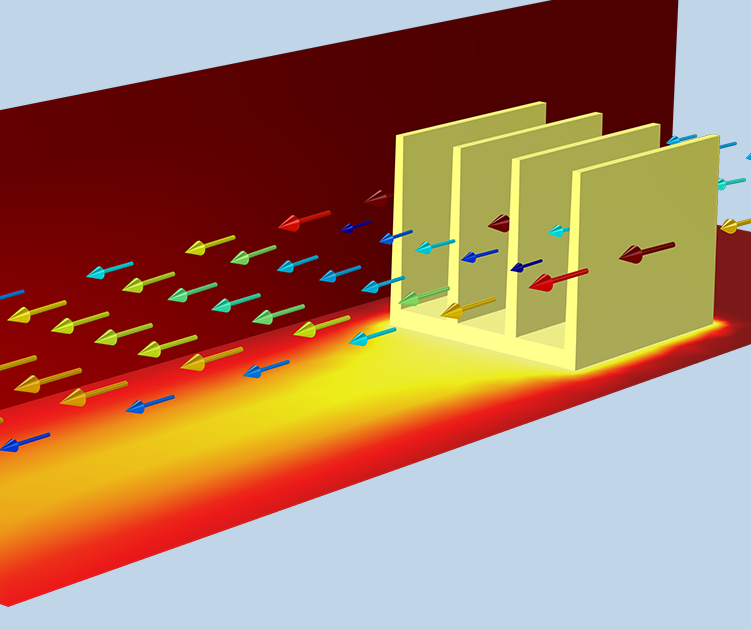

The passive cooling technology operates by enhancing natural heat dissipation from the rear surface of a solar photovoltaic (PV) module. During operation, solar panels convert only a portion of incoming solar radiation into electrical energy, while the remaining energy is converted into heat. This heat accumulates within the PV module and increases operating temperature, leading to reduced electrical efficiency and accelerated material degradation.

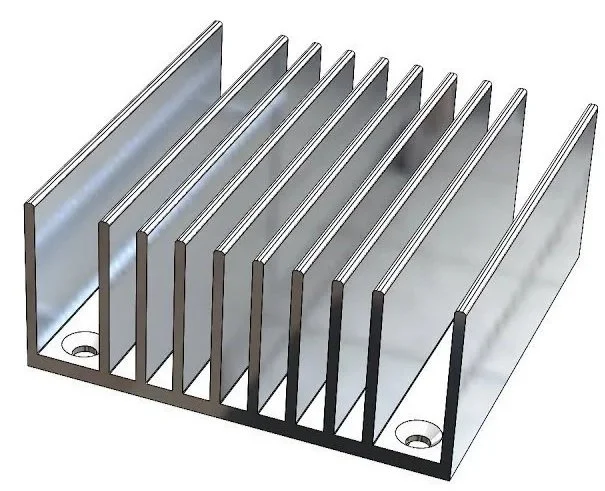

The cooling system is attached to the rear of the solar panel and consists of a high-conductivity aluminium base plate fitted with an array of engineered fins. Heat generated within the PV module is conducted through the rear surface into the aluminium base plate and then transferred to the fins. The fins increase the exposed surface area, allowing heat to be released more efficiently into the surrounding air.

Heat dissipation occurs through natural convection, where warm air rising from the fin surfaces is continuously replaced by cooler ambient air. This process requires no external energy input and is driven solely by temperature gradients between the solar module and the surrounding environment. The fin geometry, spacing, height, and thickness are engineered to promote effective airflow while maintaining structural stability and compatibility with standard PV installations.

Because the system relies entirely on passive heat transfer mechanisms, it operates continuously and reliably under real-world conditions. The absence of moving parts, fluids, or control systems ensures consistent performance in hot, dusty, and remote environments, making the technology well suited to off-grid, weak-grid, and large-scale solar installations.

Research and Development (R&D)

A research-led process combining academic insight and practical engineering to understand and address thermal performance challenges in solar PV systems.

Modelling and Simulation

Thermal and airflow simulations are used to analyse heat transfer behaviour and inform the design of effective passive cooling configurations.

Development approach

Design Optimisation

Heatsink geometry and materials are optimised to balance cooling performance, durability, cost, and manufacturability.

Prototype Fabrication

Optimised designs are fabricated using aluminium-based, scale-ready methods to assess practical production and integration.

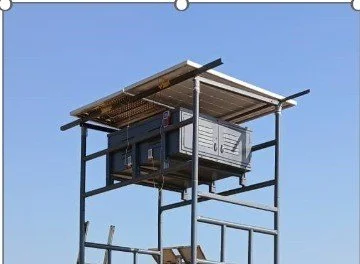

Field Testing and Validation

Prototypes are validated through real-world field trials in hot-climate environments, comparing performance against uncooled reference panels.

Scale-Up and Commercial Readiness

Validated designs are refined for early commercial deployment through cost-effective manufacturing and quality-controlled production pathways.

Grants

Jan 2024

We are excited to share that our team have won £300K from the Innovate UK "African Innovation Collaborations for Net Zero Places" funding call to develop novel heatsink technology for solar PV cells adapted to the Nigerian solar energy market.

Our team brings together leading expertise from both Nigeria and the UK, and comprises Usman Damo (MEng PhD MRAeS MIMechE CEng) and Tarig ZY Ahmed (CEng) of Hybrid Energy Systems (UK) Ltd., Finian McCann (PhD, CEng, MICE, MIMECHE) of Loughborough University, Siegfried Kwame Yeboah (CEng, MCIBSE, AMEI, FHEA, PhD), Christina Francis (MsC, PhD) and Mubarak Ismail (MSc, PhD) of London South Bank University, NASENI Solar Energy Ltd. and Professor Abubakar Sambo of the Usmanu Danfodiyo University, Sokoto.

Let’s Work Together

We’re always looking for new opportunities and are comfortable working internationally. Please get in touch and one of our project managers will contact you about beginning the proposal process.